READY IN EVOLUTION

Since 1982 we breathe innovation

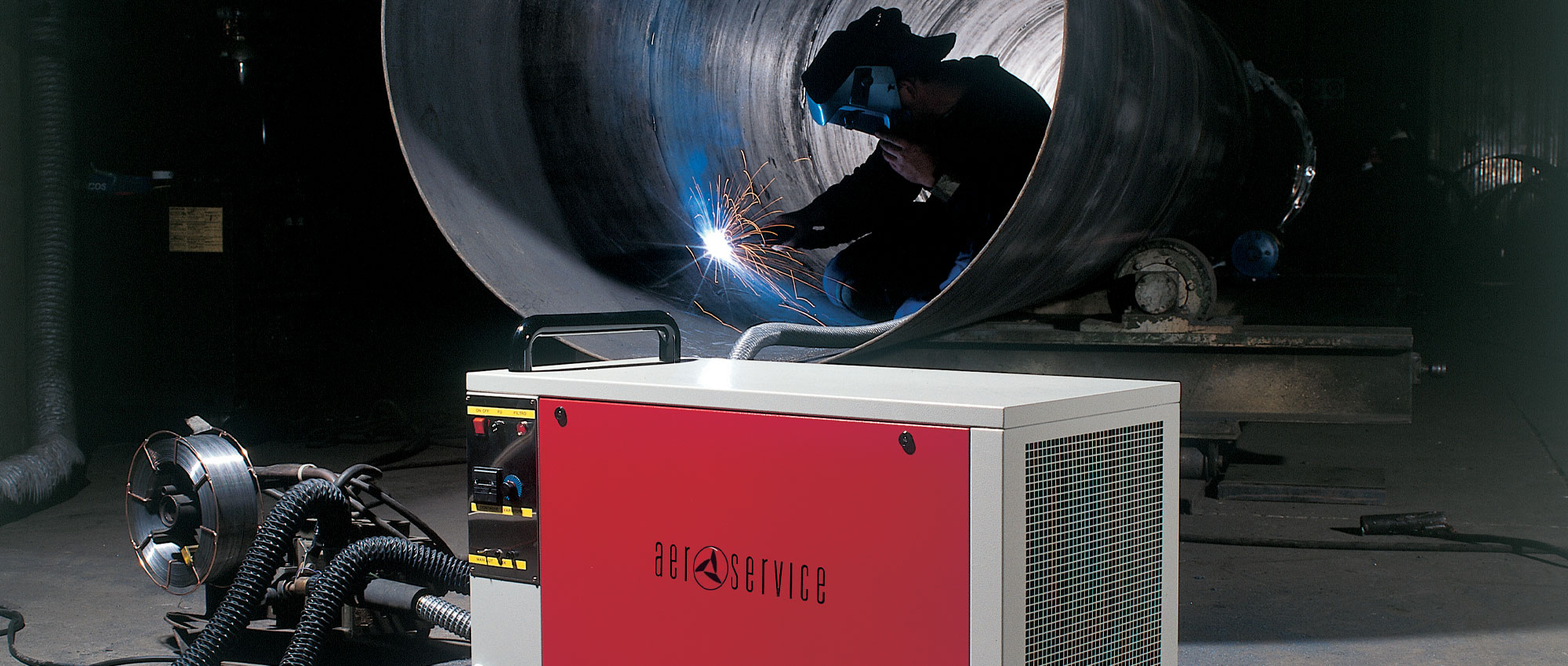

Aerservice was born in 1982 capitalizing on entrepreneurial experience in the construction of air treatment systems in the civil and industrial sector.

In a short time the Company acquires a national leadership and develops its presence in many EU and non-EU countries, thanks to a wide and varied range of products , to a technical proposal with high contents and to a modern and organized service.

Today the Division specializing in Fumes, Dust and Gas TreatmentFumes, Dust and Gas TreatmentAerservice Equipments Srl.

Read more

FEATURED PRODUCTS

From €3,045.00

To €3,721.00

From €2,458.00

To €4,152.00

From €3,870.00

To €5,671.00

From €2,695.00

To €4,496.00

From €1,995.00

To €3,826.00

From €7,250.00

To €11,996.00

From €2,367.00

To €3,092.00

DO YOU WANT TO BECOME A DISTRIBUTOR?

Click here to find out how to become one of our distributor

Deutsch

Deutsch Francais

Francais Italiano

Italiano